Remarkable Intelligent Rail transfer trolley is a type of rail transport cart commonly used in various industrial workshops such as mechanical manufacturing and metallurgical factories, as an internal support for crane transportation of heavy objects across the workshop. It has the characteristics of simple structure, high intelligence and automation, convenient use, large bearing capacity, easy maintenance, long service life, explosion-proof, low noise, safety and environmental protection.

Low-voltage rail transfer carts are powered by rails and conductive devices on the rail. The wheels and axles of the transfer carts are insulated between the wheels and without cables, which made the cart not only safe, but also anti-burned, anti-smashed, and do not affect cross transportation. It can run on curve rails, loop rails. The traveling distance won’t be limited if the transformer’s quantity increased. This series of transfer cars are easy to realize intelligent remote control and automation.

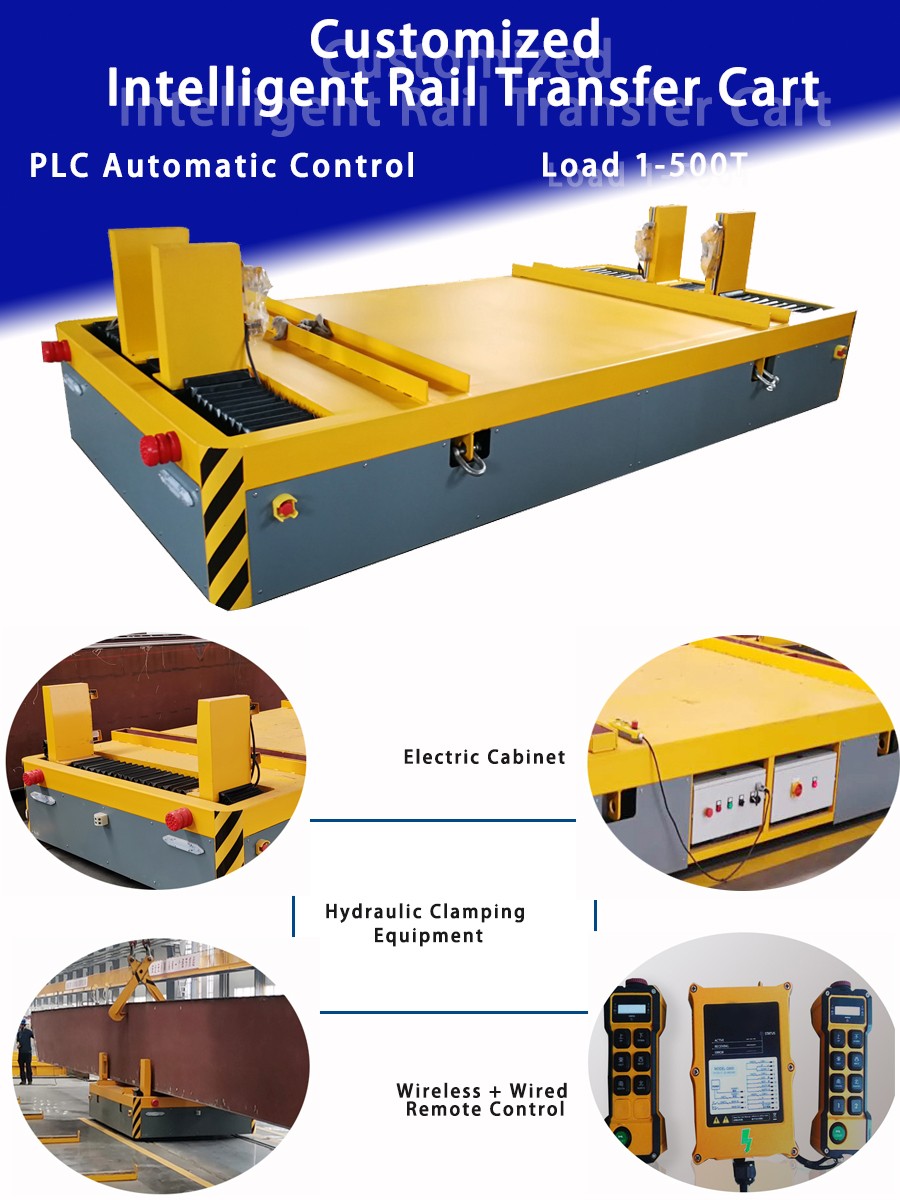

Remarkable’s intelligent low-voltage rail transfer trolleys designed and manufactured for Weihua Group have been used in its new intelligent equipment industrial park to meet the needs of large, high-end, and intelligent equipment manufacturing. Load 20 tons/25 tons, 4000×2000×600.The trolleys adopt concepts such as safe operation, advanced design, reasonable structure, simple operation, and convenient maintenance. PLC control system, stepless speed regulation frequency conversion system and safety radar device have been used to realize the intelligent remote control operation , automatic operation and automatic running between two points, automatic functions such as self-speed regulation and automatic avoidance, etc. The transfer cart is equipped with a workpiece width automatic positioning device and clamping slot, which can send a loading and unloading signal to the intelligent crane during work, and can automatically clamp and open the workpiece to achieve automatic safe transportation and unloading functions. At the same time, the biggest highlight of this cart is the connector device (automatic coupler device), which can automatically realize the hook removal and hooking operation. The docking and separation between the carts can be done by only one person to lift up a rod. Saving time, saving effort and high efficiency.

Intelligent trackless transfer cart

Intelligent trackless transfer cart

Trackless transfer cart applied in the water conservancy industry

Trackless transfer cart applied in the water conservancy industry

Motor factory handling cart 30 tons battery transfer cart

Motor factory handling cart 30 tons battery transfer cart

Industrial 30 tons hydraulic lifting heavy-duty trackless transfer cart

Industrial 30 tons hydraulic lifting heavy-duty trackless transfer cart

Customized trackless transfer cart

Customized trackless transfer cart

80 tons hydraulic steering trackless trolley

80 tons hydraulic steering trackless trolley

Intelligent trackless transfer cart

Intelligent trackless transfer cart

Trackless transfer cart applied in the water conservancy industry

Trackless transfer cart applied in the water conservancy industry

Motor factory handling cart 30 tons battery transfer cart

Motor factory handling cart 30 tons battery transfer cart

Industrial 30 tons hydraulic lifting heavy-duty trackless transfer cart

Industrial 30 tons hydraulic lifting heavy-duty trackless transfer cart

Customized trackless transfer cart

Customized trackless transfer cart

80 tons hydraulic steering trackless trolley

80 tons hydraulic steering trackless trolley

At the very beginning of formulating a solution, our engineers will predict the faults that might occur during the equipment utilization relying on their rich experience, and avoid quality risks in advance.

Before getting inside the warehouse, all steel plates must be pretreated and testified to be qualified.

There is quality inspection in every process. The previous process can be allowed to enter the next one only if it is qualified. The whole process inspection records must be well preserved.

Before delivery, all the transfer carts/trolleys must undergo performance test, including load forward and backward, obstacle avoidance, omnidirectional mobile, slope climbing, lifting, wireless remote control, etc.