Self propelled electric transfer trolley also known as AGV handling robot is used for industrial unmanned intelligent handling and material handling in explosion-proof and harsh environment. Henan Remarkable designs and manufactures AGV automatic handling robots in a wide range of fields, such as equipment manufacturing, mold manufacturing, automobile industry, household appliances, electrical appliances, computer related manufacturing industry and warehousing logistics. It is equipped with PLC electrical control, steering wheel drive system, sound and light alarm device, automatic navigation system, communication system, scheduling system, obstacle avoidance system, etc., it can also be installed with lifting device, tray, rotation and other devices. There are three control modes: hand pendant operation, remote control and computer control.

The case:

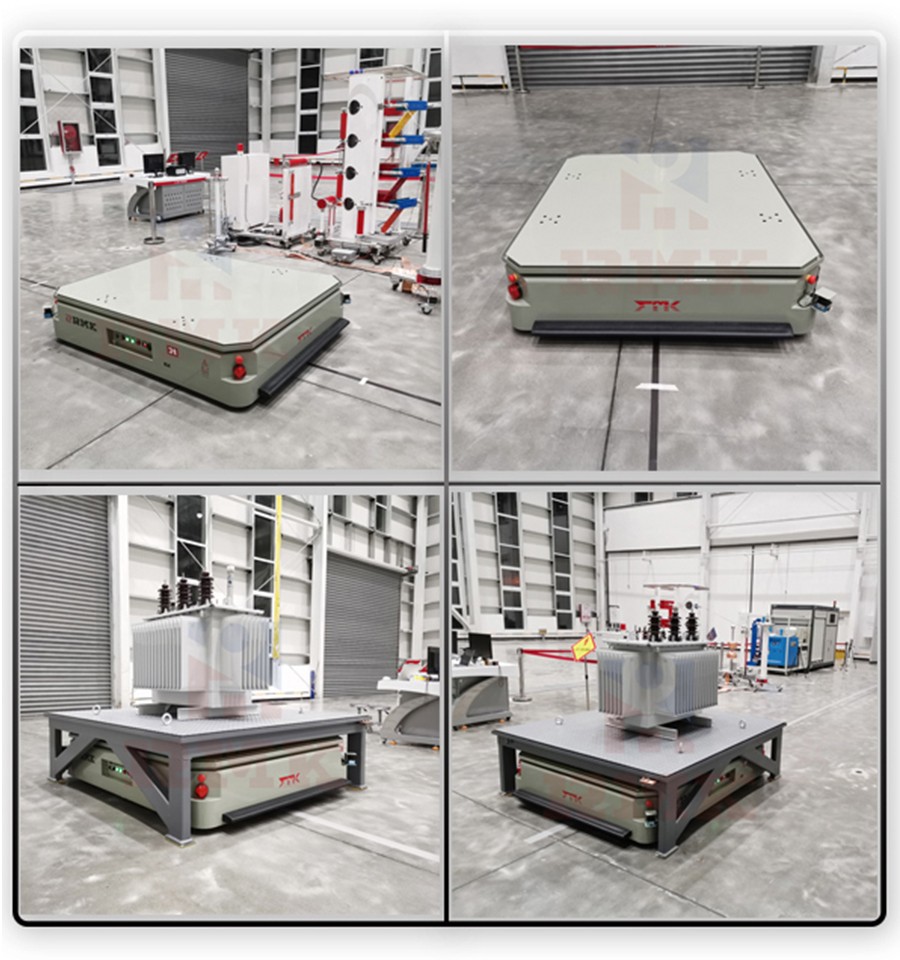

Remarkalbe designed and manufactured 3T Self propelled electric transfer trolley for China Qiyuan engineering design and Research Institute Co., Ltd. of state grid system. It is a kind of magnetic navigation transportation robot agv, which is used for the transportation of power equipment detection experiment in power grid system. AGV is equipped with laser obstacle avoidance, steering wheel system, PLC control system, dispatching system, communication system, automatic charger, computer wireless control, and hydraulic lifting platform, it can realize noiseless operation and omnidirectional mobile driving, fixed-point parking, automatic loading and unloading, intelligent charging and task allocation.

In order to meet the loading,unloading and transportation of the experimental equipment, the rack lifting table is specially designed and configured. The hydraulic lifting support is installed at the four corners of the car body. When the loading of the experimental object is required, the rack will be lifted up, and the shelf will be lowered to facilitate the experiment.

Both ends of the car body are installed with anti-collision touch edge and laser obstacle avoidance sensors. When the vehicle encounters obstacles in front of it, the sound alarm will work, and the vehicle will stop automatically when it continues to run without operation and reaches the stopping distance. If the obstacle avoidance sensor fails to work in case of low obstacle, collision avoidance contact will play a secondary role to avoid collision accidents.

With wireless communication receiving command and task scheduling and distribution system, AGV vehicle can automatically allocate work and charging requirements according to needs, complete handling according to instructions when there is a work task, and can automatically stop at a certain position for standby or charge automatically according to the power situation when there is no task.

The AGV body surface is sprayed with two layers of polyurethane topcoat. The coating is uniform, adheres firmly and the luster is more lasting.

Main technical parameters of 3 ton Self propelled electric transfer trolley magnetic navigation AGV :

NO. | Name | AGV Trackless Transfer vehicle | Remark |

1 | Load Capacity(t) | 3 | |

2 | Table Size(mm) | 1800×1500×410 | L*W*H |

3 | Ground Clearance(mm) | 50 | |

4 | Power Supply Mode | Lithium battery power supply | |

5 | Operation Mode | Intelligent automatic mode, manual control | |

6 | Motor Power(KW) | 1.5×2 | |

7 | Running Speed(m/min) | 0~30 | Stepless speed regulation |

8 | Brake Mode |

Electromagnetic brake

| |

9 | Wheel Material | Polyurethane coated tire | |

10 | Navigation mode | magnetic navigation | |

11 | Turn Mode | Steering wheel drive system | |

12 |

Adjustment of floor flatness

| Mechanical automatic regulation

| |

13 | Charge Type |

Automatic charging

| |

14 | Charger Install Type | Split style | |

15 | Charger Function | Intelligent charging | |

16 | Safety Device | Rubber bumper + laser obstacle avoidance sensor + sound and light alarm | |

17 | Other Functions |

Power display+ Overvoltage, undervoltage, overcurrent protection etc | |

Intelligent trackless transfer cart

Intelligent trackless transfer cart

Trackless transfer cart applied in the water conservancy industry

Trackless transfer cart applied in the water conservancy industry

Motor factory handling cart 30 tons battery transfer cart

Motor factory handling cart 30 tons battery transfer cart

Industrial 30 tons hydraulic lifting heavy-duty trackless transfer cart

Industrial 30 tons hydraulic lifting heavy-duty trackless transfer cart

Customized trackless transfer cart

Customized trackless transfer cart

80 tons hydraulic steering trackless trolley

80 tons hydraulic steering trackless trolley

Intelligent trackless transfer cart

Intelligent trackless transfer cart

Trackless transfer cart applied in the water conservancy industry

Trackless transfer cart applied in the water conservancy industry

Motor factory handling cart 30 tons battery transfer cart

Motor factory handling cart 30 tons battery transfer cart

Industrial 30 tons hydraulic lifting heavy-duty trackless transfer cart

Industrial 30 tons hydraulic lifting heavy-duty trackless transfer cart

Customized trackless transfer cart

Customized trackless transfer cart

80 tons hydraulic steering trackless trolley

80 tons hydraulic steering trackless trolley

At the very beginning of formulating a solution, our engineers will predict the faults that might occur during the equipment utilization relying on their rich experience, and avoid quality risks in advance.

Before getting inside the warehouse, all steel plates must be pretreated and testified to be qualified.

There is quality inspection in every process. The previous process can be allowed to enter the next one only if it is qualified. The whole process inspection records must be well preserved.

Before delivery, all the transfer carts/trolleys must undergo performance test, including load forward and backward, obstacle avoidance, omnidirectional mobile, slope climbing, lifting, wireless remote control, etc.