The automated rail transfer cart for truck inspection provided by Remarkable to customers in the railway transportation field is mainly used for inspection and maintenance work on railways and can complete the uncoupling and collaborative operation of two train carriages.

According to the work requirements, the upper computer issues the data processing system of the automated rail transfer cart (RGV) to us. The RGV data processing system sends a start signal and the displacement value for reaching the specified position to the RGV trolley that needs to run through program judgment. After the RGV trolley system receives the relevant commands, the servo drive system drives it to move. Once it reaches the position, it feeds back the in-position signal. Subsequently, the RGV data processing system sends its in-position signal to the upper computer.

The Railway shunting hook removal robot - Automated rail transfer cart is formed by stainless steel welding. It is integrally welded with longitudinal beams and cross beams as the frame and the table panel. The table surface is equipped with a detachable inspection cover plate, and there are four lifting rings on both sides for turning over and lifting. For the convenience of maintenance, an inspection window is opened on the table surface of the transmission mechanism. The frame is designed according to 125% of the rated load to prevent deformation due to impact load during loading and ensure load stiffness.

Model: RGV

Size: 2200*1200*300

Power supply mode: lithium battery

Control mode: manual wireless remote control operation + automatic intelligent online control (two modes are interlocked)

Communication mode: wired communication

Speed: 0.84m/s (normal speed); 2.2m/s (extreme high speed)

Positioning method: servo positioning. Slow down first and then stop according to the instructions of the industrial computer.

Positioning accuracy: ±10mm

Wheel material: steel core + rubber coating

Safety protection: laser obstacle avoidance, safety edge, emergency stop switch

Special requirements: waterproof protection.

Intelligent trackless transfer cart

Intelligent trackless transfer cart

Trackless transfer cart applied in the water conservancy industry

Trackless transfer cart applied in the water conservancy industry

Motor factory handling cart 30 tons battery transfer cart

Motor factory handling cart 30 tons battery transfer cart

Industrial 30 tons hydraulic lifting heavy-duty trackless transfer cart

Industrial 30 tons hydraulic lifting heavy-duty trackless transfer cart

Customized trackless transfer cart

Customized trackless transfer cart

80 tons hydraulic steering trackless trolley

80 tons hydraulic steering trackless trolley

Intelligent trackless transfer cart

Intelligent trackless transfer cart

Trackless transfer cart applied in the water conservancy industry

Trackless transfer cart applied in the water conservancy industry

Motor factory handling cart 30 tons battery transfer cart

Motor factory handling cart 30 tons battery transfer cart

Industrial 30 tons hydraulic lifting heavy-duty trackless transfer cart

Industrial 30 tons hydraulic lifting heavy-duty trackless transfer cart

Customized trackless transfer cart

Customized trackless transfer cart

80 tons hydraulic steering trackless trolley

80 tons hydraulic steering trackless trolley

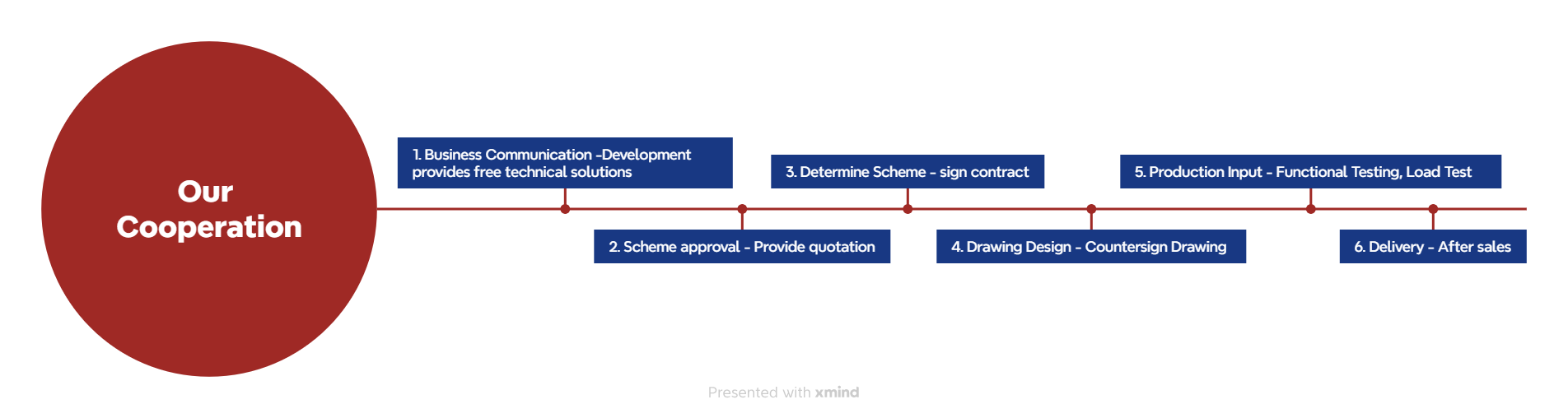

At the very beginning of formulating a solution, our engineers will predict the faults that might occur during the equipment utilization relying on their rich experience, and avoid quality risks in advance.

Before getting inside the warehouse, all steel plates must be pretreated and testified to be qualified.

There is quality inspection in every process. The previous process can be allowed to enter the next one only if it is qualified. The whole process inspection records must be well preserved.

Before delivery, all the transfer carts/trolleys must undergo performance test, including load forward and backward, obstacle avoidance, omnidirectional mobile, slope climbing, lifting, wireless remote control, etc.