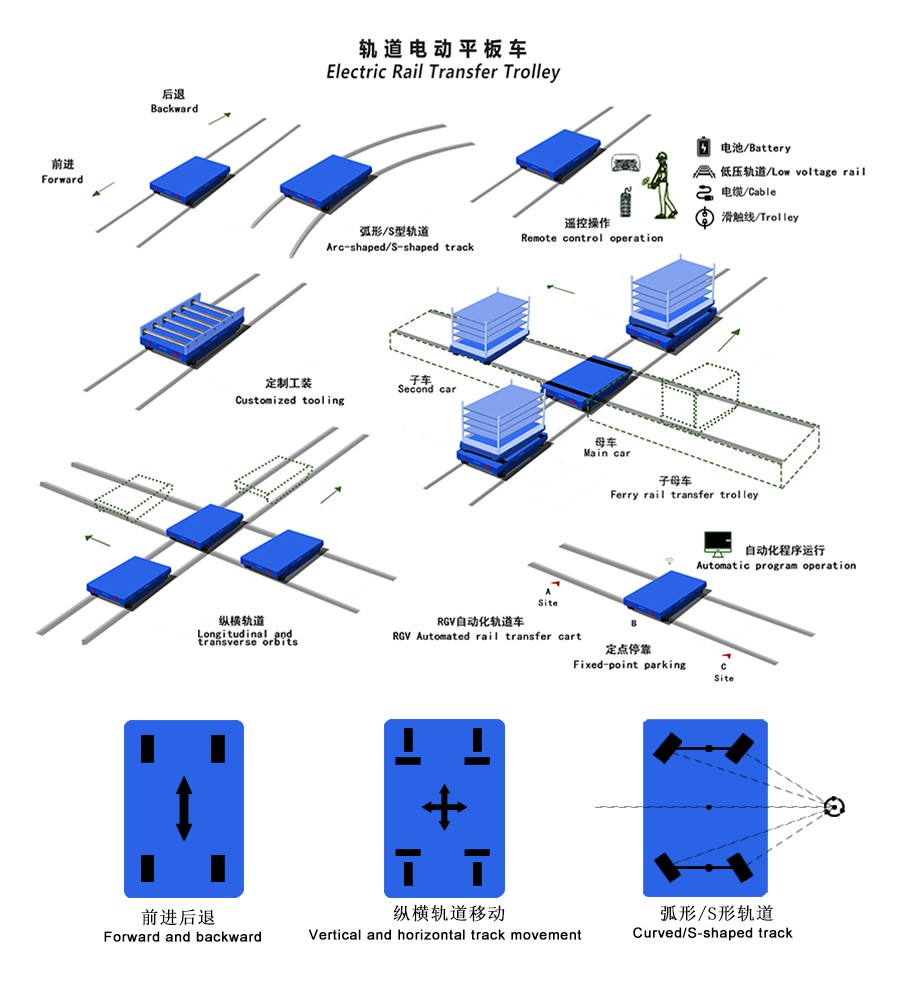

Two-car linked rail transfer cart can transport larger and heavier materials and workpieces, effectively solving the material handling problems in industrial production, rail transit, logistics and warehousing and other fields.

We design and customize a 40-ton + 40-ton two-car linked rail transfer cart for customers. It can carry up to more than 80 tons, move along longitudinal and transverse rails, and has an automated program. It is used for efficient transportation and handling in customers' container production.

The principle of the two-car linked rail transfer cart is realized through an electrical control system. On the two-car linked rail trolley, sensors and controllers are usually installed to monitor and control the running state of the trolley.

When two trolleys need to run in linkage, the sensors will detect information such as the position and speed of the vehicles and transmit this information to the controller. The controller will calculate the distance and relative speed between the two vehicles according to the feedback information of the sensors, and realize the synchronous running of the two vehicles by controlling the rotational speed and steering of the motor.

Intelligent trackless transfer cart

Intelligent trackless transfer cart

Trackless transfer cart applied in the water conservancy industry

Trackless transfer cart applied in the water conservancy industry

Motor factory handling cart 30 tons battery transfer cart

Motor factory handling cart 30 tons battery transfer cart

Industrial 30 tons hydraulic lifting heavy-duty trackless transfer cart

Industrial 30 tons hydraulic lifting heavy-duty trackless transfer cart

Customized trackless transfer cart

Customized trackless transfer cart

80 tons hydraulic steering trackless trolley

80 tons hydraulic steering trackless trolley

Intelligent trackless transfer cart

Intelligent trackless transfer cart

Trackless transfer cart applied in the water conservancy industry

Trackless transfer cart applied in the water conservancy industry

Motor factory handling cart 30 tons battery transfer cart

Motor factory handling cart 30 tons battery transfer cart

Industrial 30 tons hydraulic lifting heavy-duty trackless transfer cart

Industrial 30 tons hydraulic lifting heavy-duty trackless transfer cart

Customized trackless transfer cart

Customized trackless transfer cart

80 tons hydraulic steering trackless trolley

80 tons hydraulic steering trackless trolley

At the very beginning of formulating a solution, our engineers will predict the faults that might occur during the equipment utilization relying on their rich experience, and avoid quality risks in advance.

Before getting inside the warehouse, all steel plates must be pretreated and testified to be qualified.

There is quality inspection in every process. The previous process can be allowed to enter the next one only if it is qualified. The whole process inspection records must be well preserved.

Before delivery, all the transfer carts/trolleys must undergo performance test, including load forward and backward, obstacle avoidance, omnidirectional mobile, slope climbing, lifting, wireless remote control, etc.