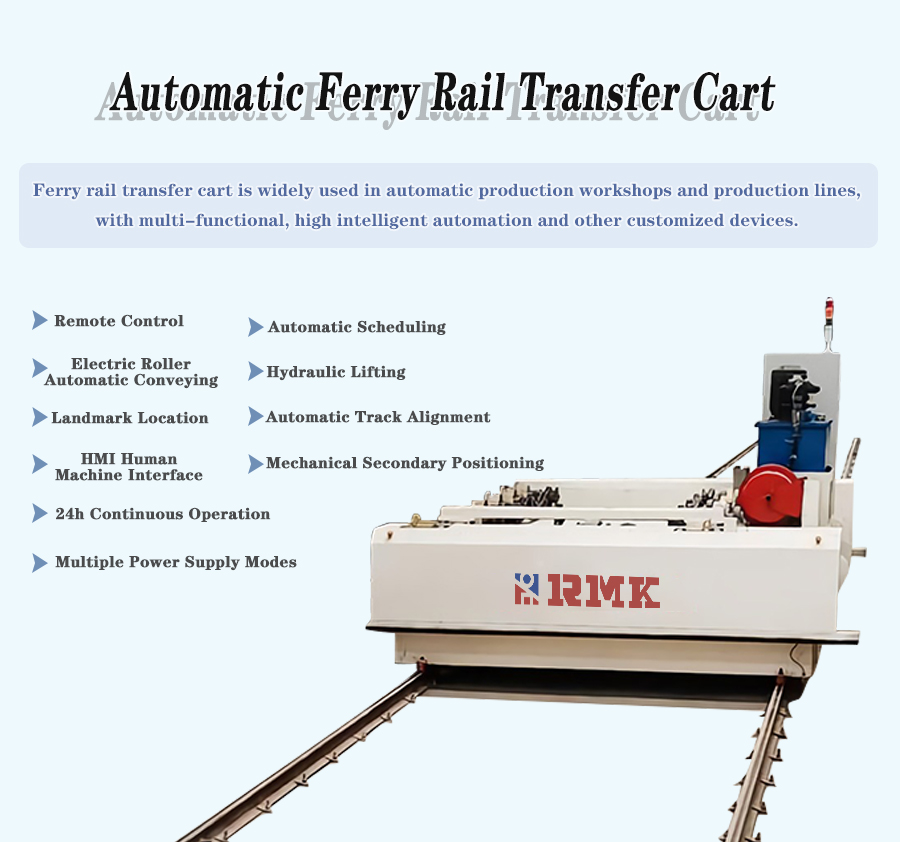

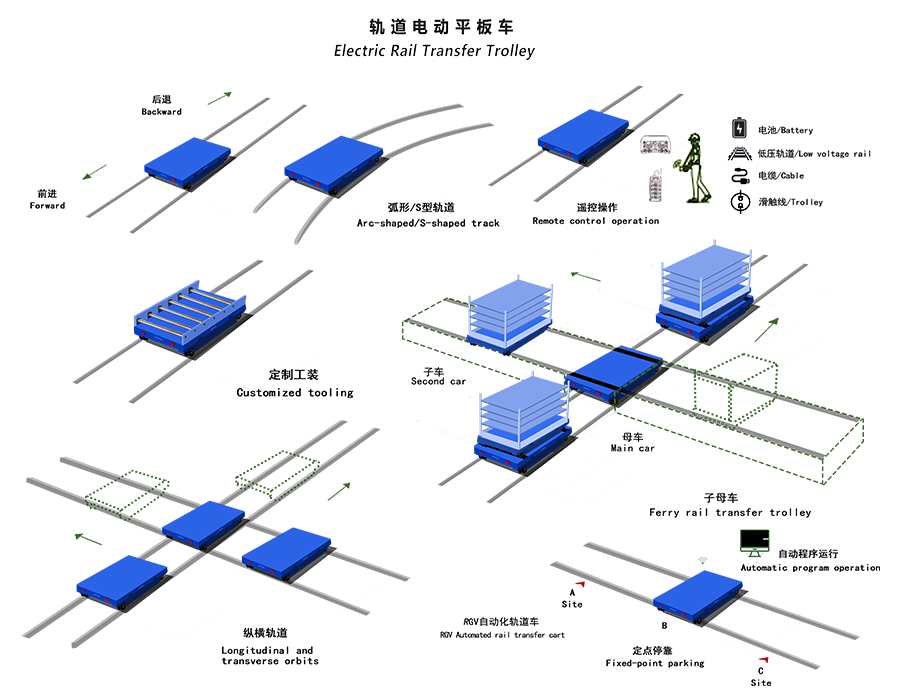

Automated rail transfer trolley is applied to various industrial transportation, including coils, construction, steel, heavy equipment manufacturing, military, explosion-proof, chemical and other industries. There are various models of Remarkable automated rail transfer trolley including linear moving, curved moving, longitudinal and transverse rail and ferry type.

The Ferry type automated rail transfer trolley is divided into upper and lower body, with the lower trolley used for transportation and the upper car used for ferry and cargo handling.

We need to understand the specific layout and requirements of the customer's on-site transportation, and tailor an economical and reasonable transportation solution that suits and satisfies the customer's requirements. For example, the size of the upper and lower body of the ferry transfer trolley, the power supply method, the degree of automation, whether to customize the opposite surface according to the nature of the transported materials, and so on.

1.What are the specific layout and automation requirements for customer on-site transportation? Do you know that each customer has different requirements, such as precision requirements, docking points, and interconnection with third-party devices.

2. The size requirements for the upper and lower car bodies, and the lower car body rail must be accurately aligned with the track installed in another area. Otherwise, the upper level car will not be able to pass smoothly.

3. What is the method used for the lower level trolley and the upper level trolley? Battery or cable reel. Cable drum power supply, the running distance of the trolley cannot exceed 150 meters

4. V-shaped brackets are commonly used for transporting industrial steel coils, and we also have other equipment or functions such as lifting and roller conveyor lines.

Intelligent trackless transfer cart

Intelligent trackless transfer cart

Trackless transfer cart applied in the water conservancy industry

Trackless transfer cart applied in the water conservancy industry

Motor factory handling cart 30 tons battery transfer cart

Motor factory handling cart 30 tons battery transfer cart

Industrial 30 tons hydraulic lifting heavy-duty trackless transfer cart

Industrial 30 tons hydraulic lifting heavy-duty trackless transfer cart

Customized trackless transfer cart

Customized trackless transfer cart

80 tons hydraulic steering trackless trolley

80 tons hydraulic steering trackless trolley

Intelligent trackless transfer cart

Intelligent trackless transfer cart

Trackless transfer cart applied in the water conservancy industry

Trackless transfer cart applied in the water conservancy industry

Motor factory handling cart 30 tons battery transfer cart

Motor factory handling cart 30 tons battery transfer cart

Industrial 30 tons hydraulic lifting heavy-duty trackless transfer cart

Industrial 30 tons hydraulic lifting heavy-duty trackless transfer cart

Customized trackless transfer cart

Customized trackless transfer cart

80 tons hydraulic steering trackless trolley

80 tons hydraulic steering trackless trolley

At the very beginning of formulating a solution, our engineers will predict the faults that might occur during the equipment utilization relying on their rich experience, and avoid quality risks in advance.

Before getting inside the warehouse, all steel plates must be pretreated and testified to be qualified.

There is quality inspection in every process. The previous process can be allowed to enter the next one only if it is qualified. The whole process inspection records must be well preserved.

Before delivery, all the transfer carts/trolleys must undergo performance test, including load forward and backward, obstacle avoidance, omnidirectional mobile, slope climbing, lifting, wireless remote control, etc.