The 40-ton Omnimove transfer cart with dual platforms is an efficient transportation equipment customized for our Swiss customer. The Swiss customer is a furniture design and manufacturer. The transfer cart is used to move and transport materials and finished products in large-scale furniture production.

Dual-platform structure: This transfer cart has two independent platforms. Each platform can be operated independently or work collaboratively as needed. The dual-platform design increases the flexibility and functionality of the transfer cart, enabling it to transport or transfer goods or equipment of different types and sizes simultaneously. For example, one platform can be used to place large and heavy equipment, and the other platform can be used to place related accessories or tools.

At the same time, the platform is equipped with hydraulic and weighing mechanisms, which can lift 150mm and weigh and detect the transported goods.

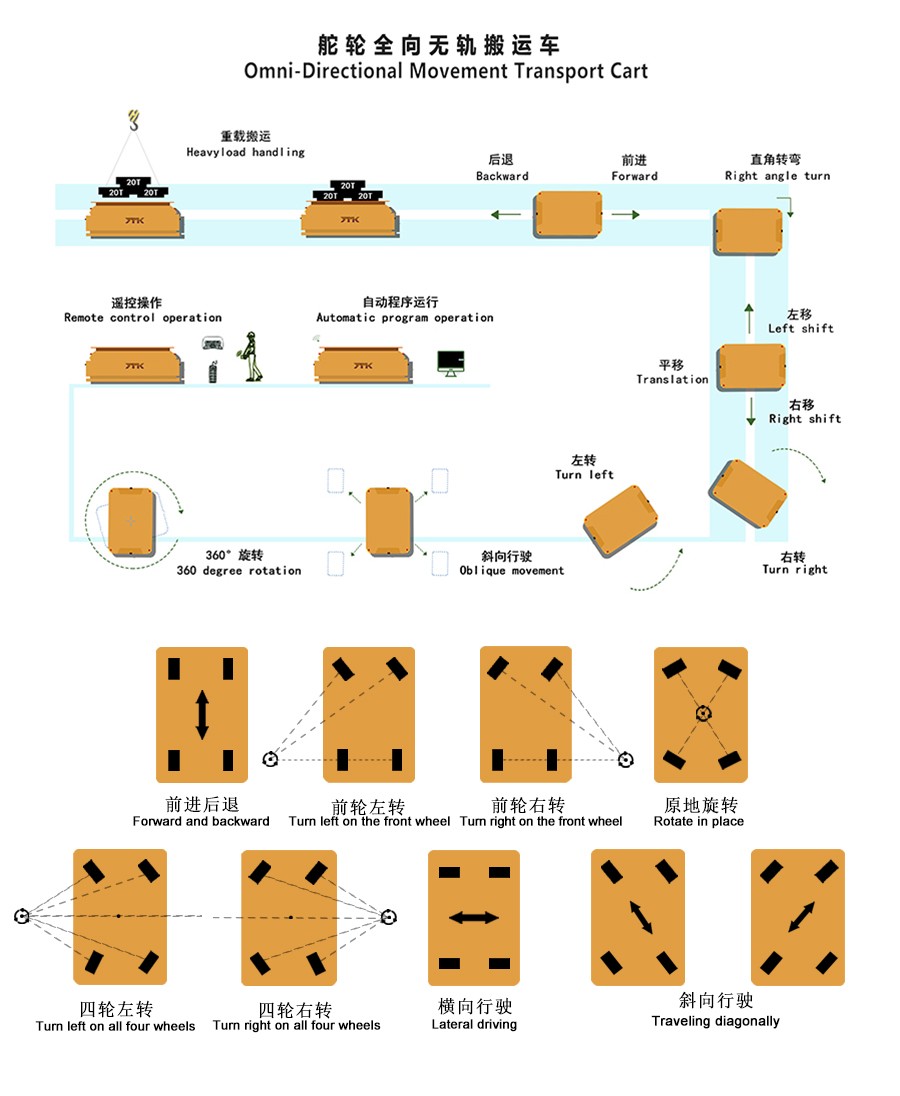

Omnimove transfer cart function: By adopting special wheel designs such as Mecanum wheels or steering wheels, the transfer cart can achieve omni-directional movement, including forward, backward, lateral movement, oblique movement, and rotation in place. This omni-directional movement ability enables the transfer cart to drive and turn flexibly in narrow spaces or complex working environments, greatly improving its applicability and maneuverability.

Intelligent control:

Easy operation: Usually equipped with an advanced control system, operators can operate the transfer cart through a remote control, control panel, or by networking with other intelligent devices. The operation interface is friendly and easy to use, greatly reducing the training cost and operation difficulty for operators.

Model:RWP-40T

Rated Loading capacity(T):40

Max impact load (T):48

Table Size(mm):7000*2200*900(L*W*H)

Lifting Height(mm):150

Lifting Table:dual platforms 1800*2000

Wheel Material:ZG55+ polyurethane wheel

Wheel Quantity:8

Intelligent trackless transfer cart

Intelligent trackless transfer cart

Trackless transfer cart applied in the water conservancy industry

Trackless transfer cart applied in the water conservancy industry

Motor factory handling cart 30 tons battery transfer cart

Motor factory handling cart 30 tons battery transfer cart

Industrial 30 tons hydraulic lifting heavy-duty trackless transfer cart

Industrial 30 tons hydraulic lifting heavy-duty trackless transfer cart

Customized trackless transfer cart

Customized trackless transfer cart

80 tons hydraulic steering trackless trolley

80 tons hydraulic steering trackless trolley

Intelligent trackless transfer cart

Intelligent trackless transfer cart

Trackless transfer cart applied in the water conservancy industry

Trackless transfer cart applied in the water conservancy industry

Motor factory handling cart 30 tons battery transfer cart

Motor factory handling cart 30 tons battery transfer cart

Industrial 30 tons hydraulic lifting heavy-duty trackless transfer cart

Industrial 30 tons hydraulic lifting heavy-duty trackless transfer cart

Customized trackless transfer cart

Customized trackless transfer cart

80 tons hydraulic steering trackless trolley

80 tons hydraulic steering trackless trolley

At the very beginning of formulating a solution, our engineers will predict the faults that might occur during the equipment utilization relying on their rich experience, and avoid quality risks in advance.

Before getting inside the warehouse, all steel plates must be pretreated and testified to be qualified.

There is quality inspection in every process. The previous process can be allowed to enter the next one only if it is qualified. The whole process inspection records must be well preserved.

Before delivery, all the transfer carts/trolleys must undergo performance test, including load forward and backward, obstacle avoidance, omnidirectional mobile, slope climbing, lifting, wireless remote control, etc.