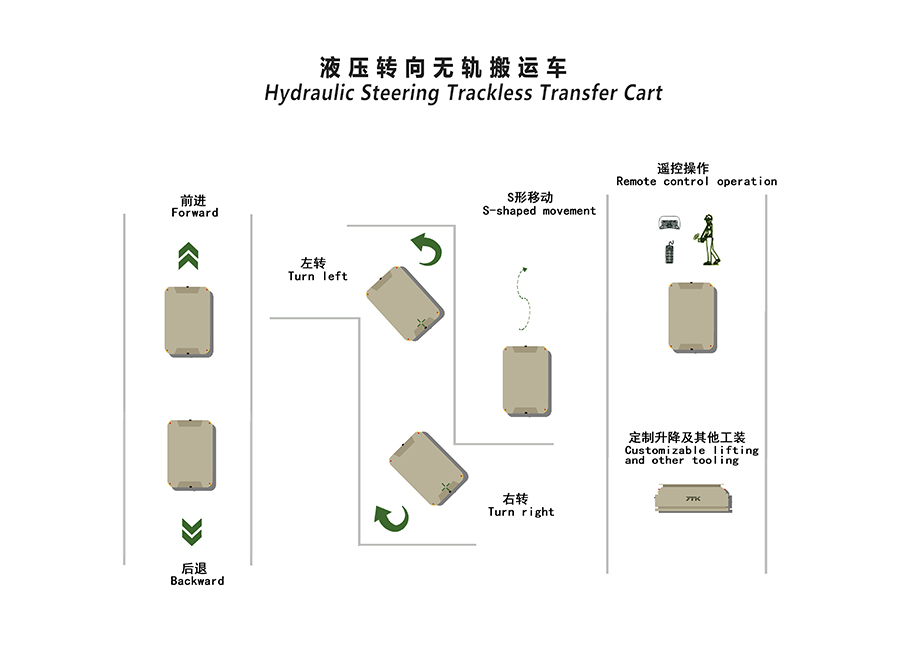

30 Tons trackless cart adopts hydraulic steering and maintenance free battery power supply. It has two control modes: on-board handle and wireless remote control. It uses polyurethane coated wheels, which have excellent wear resistance and permeability, and can be used in harsh environments and various oils, effectively extending its service life. At the same time, it can maintain good toughness at low temperatures and adapt to various extreme environments.

The cart body is equipped with a lifting device, which adopts a local lifting mode at both ends of the table, allowing synchronous lifting at both ends. One end of the table can be selected for lifting, allowing for free switching, flexibility, and convenience. RMK has a lot of experience in heavy-duty and intelligent trackless handling carts, customizing trackless electric flatcars for customers with different needs, suitable for various fields and industries.

30 Tons Omnidirectional Mobile Steering Wheel Electric transfer cart

30 Tons Omnidirectional Mobile Steering Wheel Electric transfer cart

60 Tons Heavy Duty Hydraulic Lifting Trackless Cart

60 Tons Heavy Duty Hydraulic Lifting Trackless Cart

30 Tons Heavy Duty Hydraulic Lifting Trackless Cart

30 Tons Heavy Duty Hydraulic Lifting Trackless Cart

Intelligent trackless transfer cart

Intelligent trackless transfer cart

Trackless transfer cart applied in the water conservancy industry

Trackless transfer cart applied in the water conservancy industry

Motor factory handling cart 30 tons battery transfer cart

Motor factory handling cart 30 tons battery transfer cart

30 Tons Omnidirectional Mobile Steering Wheel Electric transfer cart

30 Tons Omnidirectional Mobile Steering Wheel Electric transfer cart

60 Tons Heavy Duty Hydraulic Lifting Trackless Cart

60 Tons Heavy Duty Hydraulic Lifting Trackless Cart

30 Tons Heavy Duty Hydraulic Lifting Trackless Cart

30 Tons Heavy Duty Hydraulic Lifting Trackless Cart

Intelligent trackless transfer cart

Intelligent trackless transfer cart

Trackless transfer cart applied in the water conservancy industry

Trackless transfer cart applied in the water conservancy industry

Motor factory handling cart 30 tons battery transfer cart

Motor factory handling cart 30 tons battery transfer cart

At the very beginning of formulating a solution, our engineers will predict the faults that might occur during the equipment utilization relying on their rich experience, and avoid quality risks in advance.

Before getting inside the warehouse, all steel plates must be pretreated and testified to be qualified.

There is quality inspection in every process. The previous process can be allowed to enter the next one only if it is qualified. The whole process inspection records must be well preserved.

Before delivery, all the transfer carts/trolleys must undergo performance test, including load forward and backward, obstacle avoidance, omnidirectional mobile, slope climbing, lifting, wireless remote control, etc.