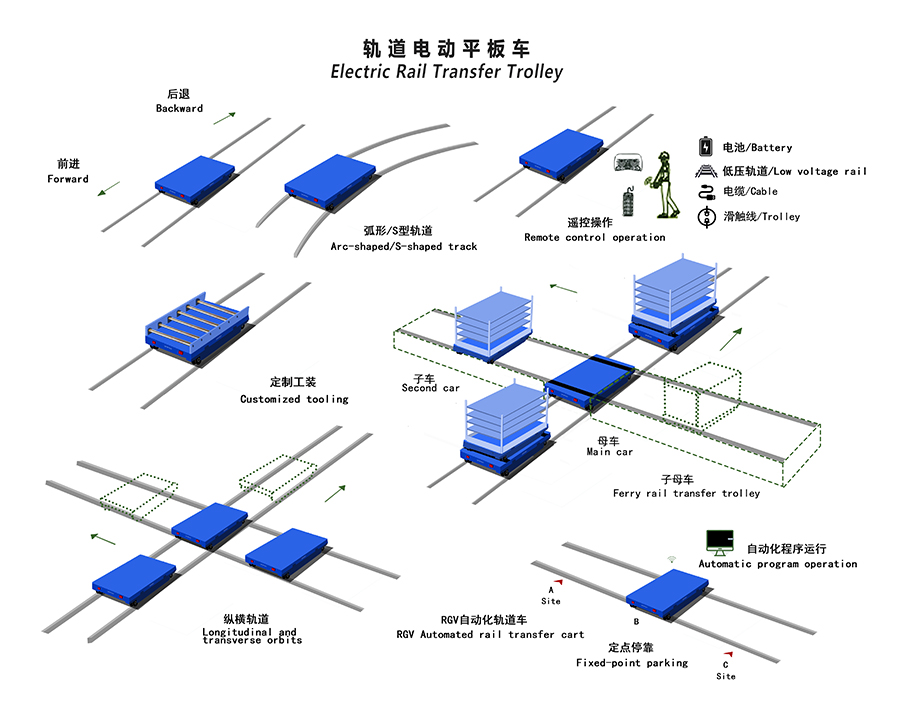

The automated RGV track cart weighs 3 tons and can operate on curved tracks and S-shaped tracks. RMK has a mother and son type rail cart and a longitudinal and transverse moving rail cart. The longitudinal and transverse moving automated rail transfer cart can operate on the longitudinal and transverse crossing tracks, achieve track recognition and positioning, and switch track operation trajectories. According to the needs, multiple handling modes such as mechanical arms and cranes can be customized on the transfer cart platform, as well as various automation functions and programs.

At the very beginning of formulating a solution, our engineers will predict the faults that might occur during the equipment utilization relying on their rich experience, and avoid quality risks in advance.

Before getting inside the warehouse, all steel plates must be pretreated and testified to be qualified.

There is quality inspection in every process. The previous process can be allowed to enter the next one only if it is qualified. The whole process inspection records must be well preserved.

Before delivery, all the transfer carts/trolleys must undergo performance test, including load forward and backward, obstacle avoidance, omnidirectional mobile, slope climbing, lifting, wireless remote control, etc.