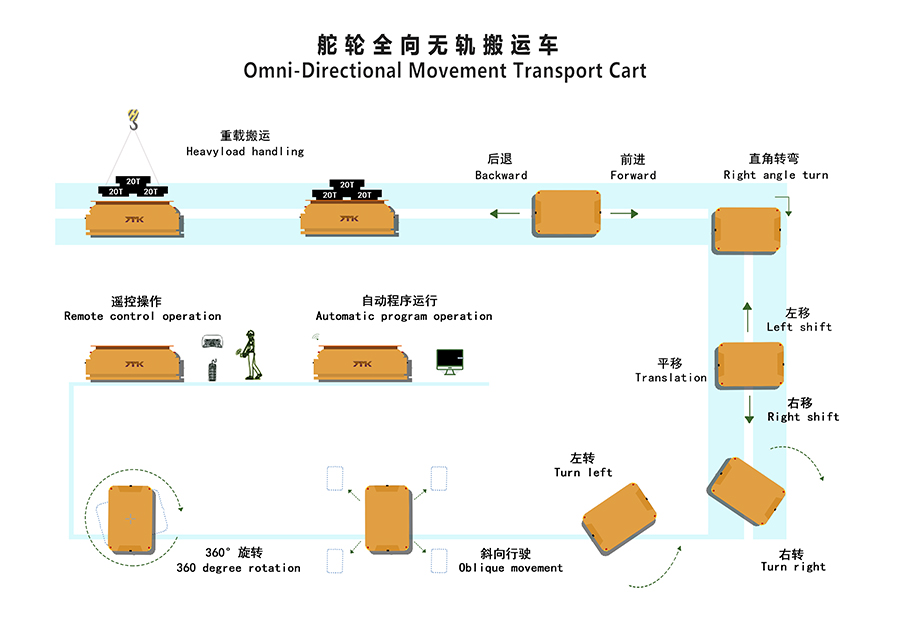

The steering wheel omnidirectional cart, also known as the longitudinal and transverse moving trackless transport cart, can withstand a load of 160 tons. It adopts two types of wheel sets: single steering wheel sets and double differential wheels. Depending on different application scenarios and working conditions, different wheel sets can be used. It is composed of the cart body, driving system (composed of battery, motor, reducer), electrical system, steering wheel system, and safety detection system. The whole cart is very convenient to operate, with low noise and flexible operation. It can automatically stop when encountering people or objects, which not only improves work efficiency but also avoids safety hazards.

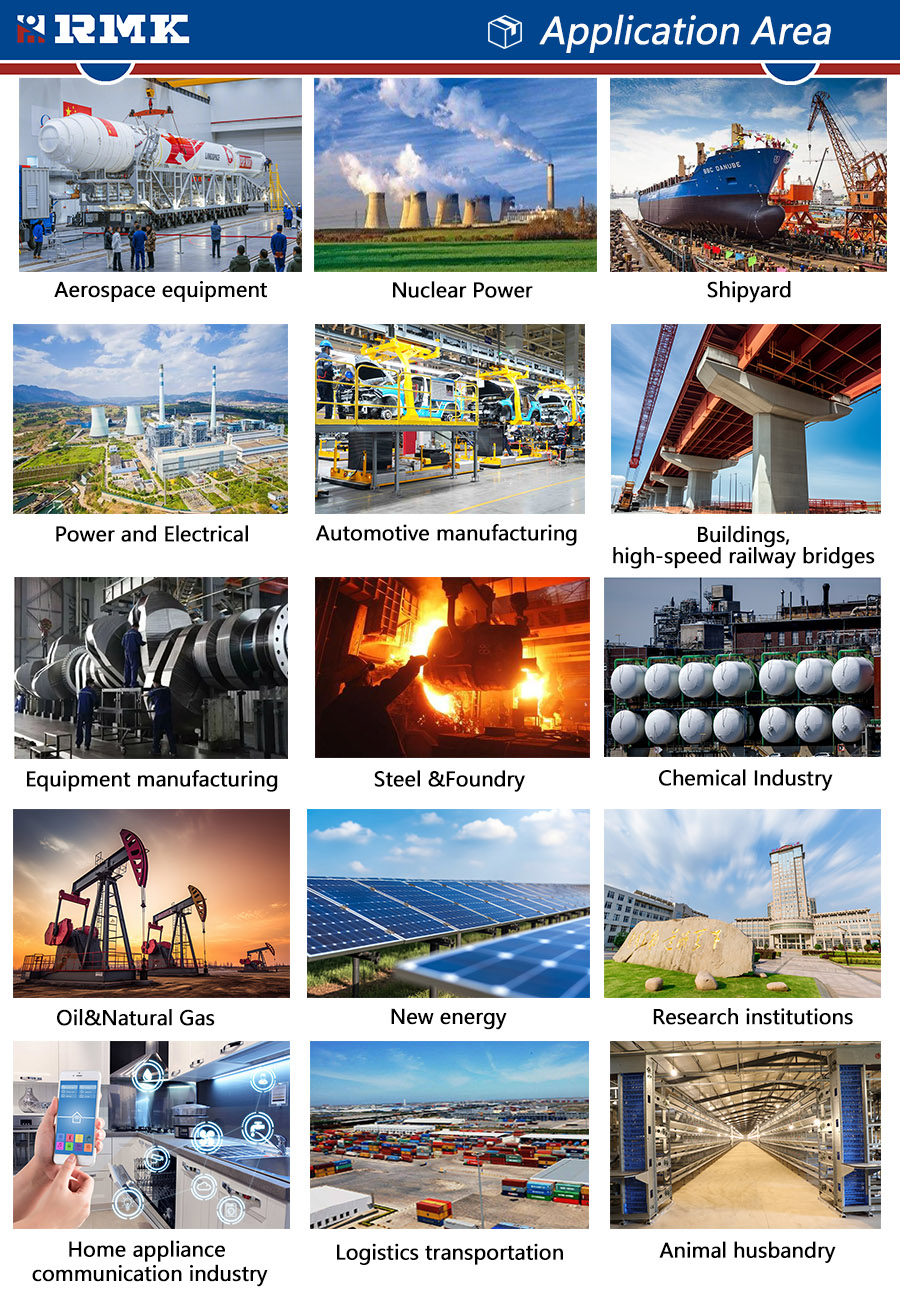

The steering wheel AGV adopts high-strength polyurethane rubber wheels as the driving and cartrying wheels, achieving heavy-duty transportation within the factory building. It can walk freely and turn freely on the field without being limited by space and ground. It can move forward, backward, left and right, translate and move diagonally, rotate 360 °in place, etc. It is suitable for use on sites with relatively unstable operating paths. Widely used in many fields such as aviation and aerospace, rail transit, wind power, engineering machinery, national defense science and engineering, warehousing and logistics, the trackless handling cart with steering wheel system is more flexible. It can move vertically and horizontally to convert into horizontal movement, and can also move longitudinally and obliquely. It can rotate in place within limited space and is suitable for complex production environments and limited production spaces and narrow paths. It can freely shuttle between various sites and environments, and the operation of the cart is also more intelligent and convenient. Currently, it is mainly used for the operation of various materials such as molds, workpieces, and equipment, and can also be used in various three-dimensional warehouses with the addition of automation programs.

160 tonS heavy-duty omnidirectional steering wheel transfer cart

160 tonS heavy-duty omnidirectional steering wheel transfer cart

Intelligent trackless transfer cart

Intelligent trackless transfer cart

Trackless transfer cart applied in the water conservancy industry

Trackless transfer cart applied in the water conservancy industry

Motor factory handling cart 30 tons battery transfer cart

Motor factory handling cart 30 tons battery transfer cart

Industrial 30 tons hydraulic lifting heavy-duty trackless transfer cart

Industrial 30 tons hydraulic lifting heavy-duty trackless transfer cart

Customized trackless transfer cart

Customized trackless transfer cart

160 tonS heavy-duty omnidirectional steering wheel transfer cart

160 tonS heavy-duty omnidirectional steering wheel transfer cart

Intelligent trackless transfer cart

Intelligent trackless transfer cart

Trackless transfer cart applied in the water conservancy industry

Trackless transfer cart applied in the water conservancy industry

Motor factory handling cart 30 tons battery transfer cart

Motor factory handling cart 30 tons battery transfer cart

Industrial 30 tons hydraulic lifting heavy-duty trackless transfer cart

Industrial 30 tons hydraulic lifting heavy-duty trackless transfer cart

Customized trackless transfer cart

Customized trackless transfer cart

At the very beginning of formulating a solution, our engineers will predict the faults that might occur during the equipment utilization relying on their rich experience, and avoid quality risks in advance.

Before getting inside the warehouse, all steel plates must be pretreated and testified to be qualified.

There is quality inspection in every process. The previous process can be allowed to enter the next one only if it is qualified. The whole process inspection records must be well preserved.

Before delivery, all the transfer carts/trolleys must undergo performance test, including load forward and backward, obstacle avoidance, omnidirectional mobile, slope climbing, lifting, wireless remote control, etc.