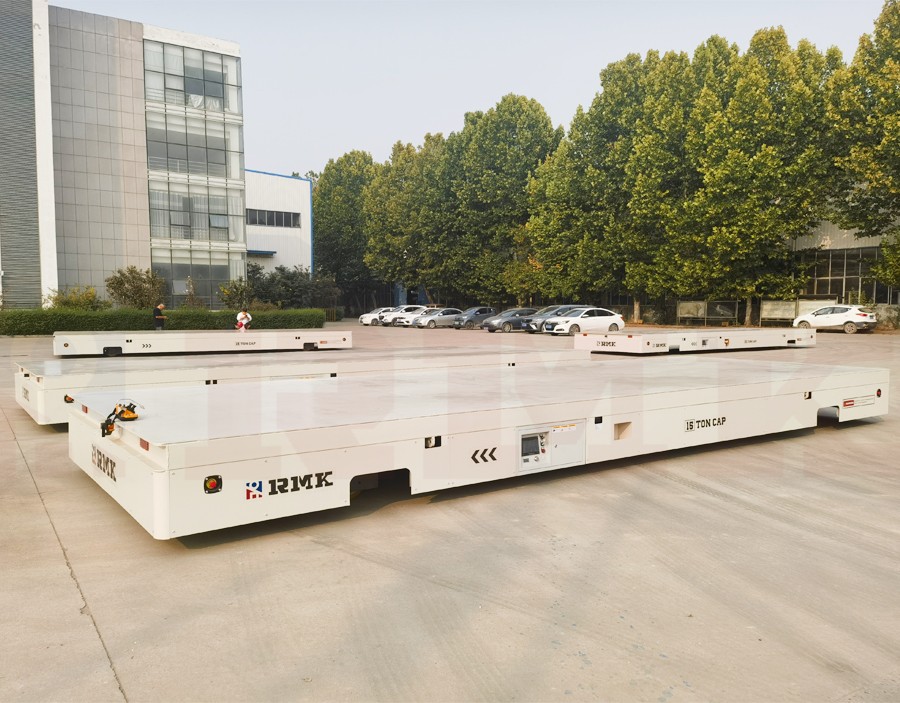

Trackless electric transport vehicles are material handling equipment that do not require the laying of tracks and travel on flat and hardened ground. Its power is provided by a battery installed inside the flat car. Through the on-board electrical control system, power is provided to the DC traction motor, and the functions of starting, stopping, advancing, retreating, turning, etc. of the flat car are achieved through handheld operating handles (wired or wireless) for operation and control.

The difference from track electric flat cars is that their operation is not restricted by the track trajectory, and they can turn and run freely.

The difference from steering wheel type transport vehicles is that they have a short body, high load-bearing capacity, flexible operation, and can be remotely operated.

Trackless electric transport vehicles can achieve 360 ° turning in place and vertical and horizontal running in place.

The disadvantage of trackless electric transport vehicles is that the battery power supply is limited by the power supply time, and attention needs to be paid to charging and daily management of the battery.

The length, width, height, operating speed, and platform requirements of the trackless electric transport vehicle can be customized according to the customer's process requirements

Intelligent trackless transfer cart

Intelligent trackless transfer cart

Trackless transfer cart applied in the water conservancy industry

Trackless transfer cart applied in the water conservancy industry

Motor factory handling cart 30 tons battery transfer cart

Motor factory handling cart 30 tons battery transfer cart

Industrial 30 tons hydraulic lifting heavy-duty trackless transfer cart

Industrial 30 tons hydraulic lifting heavy-duty trackless transfer cart

Customized trackless transfer cart

Customized trackless transfer cart

80 tons hydraulic steering trackless trolley

80 tons hydraulic steering trackless trolley

Intelligent trackless transfer cart

Intelligent trackless transfer cart

Trackless transfer cart applied in the water conservancy industry

Trackless transfer cart applied in the water conservancy industry

Motor factory handling cart 30 tons battery transfer cart

Motor factory handling cart 30 tons battery transfer cart

Industrial 30 tons hydraulic lifting heavy-duty trackless transfer cart

Industrial 30 tons hydraulic lifting heavy-duty trackless transfer cart

Customized trackless transfer cart

Customized trackless transfer cart

80 tons hydraulic steering trackless trolley

80 tons hydraulic steering trackless trolley

At the very beginning of formulating a solution, our engineers will predict the faults that might occur during the equipment utilization relying on their rich experience, and avoid quality risks in advance.

Before getting inside the warehouse, all steel plates must be pretreated and testified to be qualified.

There is quality inspection in every process. The previous process can be allowed to enter the next one only if it is qualified. The whole process inspection records must be well preserved.

Before delivery, all the transfer carts/trolleys must undergo performance test, including load forward and backward, obstacle avoidance, omnidirectional mobile, slope climbing, lifting, wireless remote control, etc.