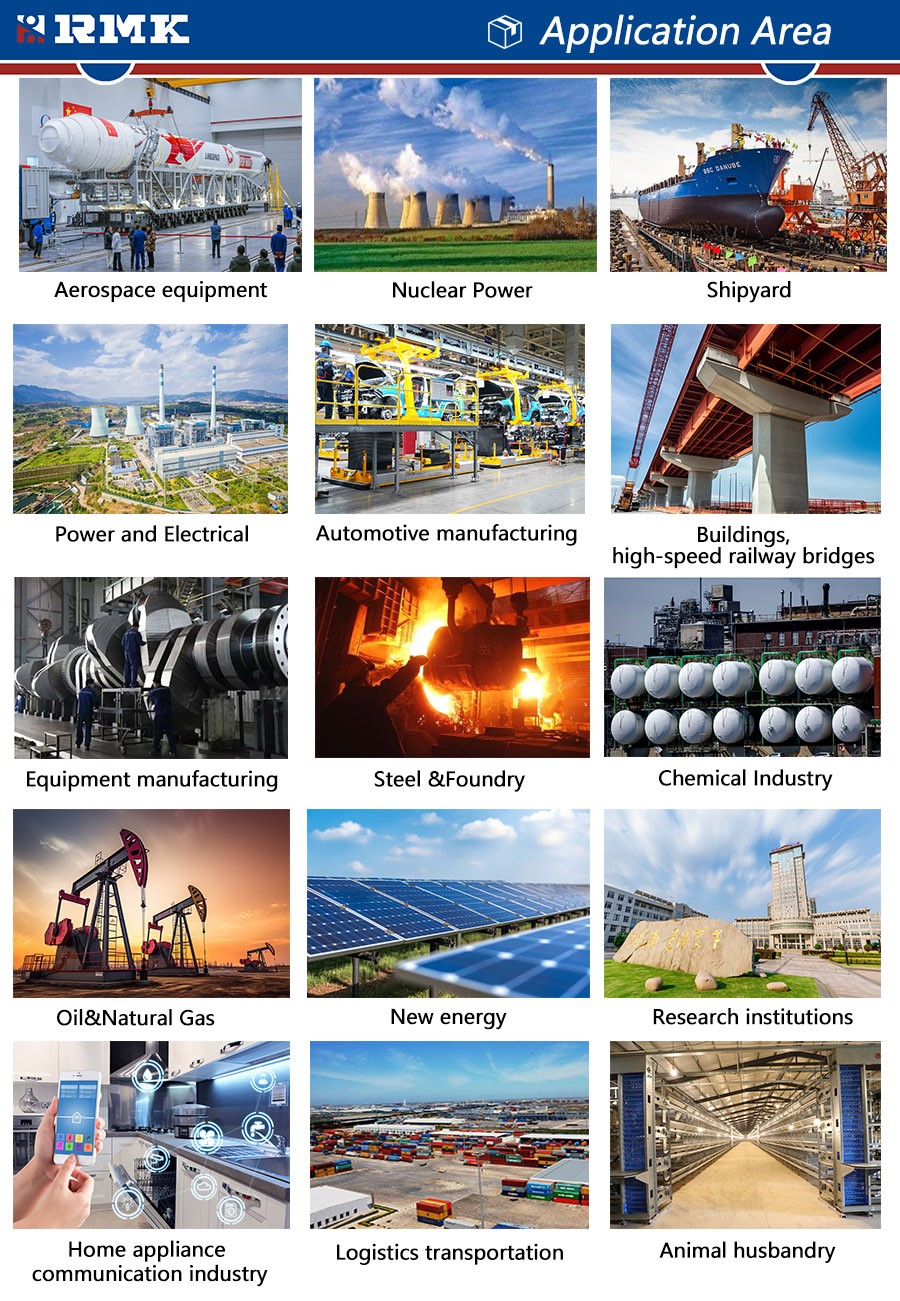

10 tons trackless electric transfer cart, exported to Bulgaria, using polyurethane coated wheels and powered by maintenance free lead-acid batteries. Application scope: mechanical manufacturing, automotive industry, heavy industry manufacturing, mold manufacturing, engineering machinery, shipbuilding, port freight yards, steel plate distribution, steel metallurgy, mining transportation, aerospace, military and other industries.

The characteristics of polyurethane coated wheels are as follows:

1. Wear resistance: Its wear resistance is very outstanding, generally within the range of 0.01-0.10 (cm3)/1.61km, about 3-5 times that of rubber.

2. Flame retardancy: The wheel body is made of polyurethane material coated with adhesive, ensuring its reliable flame retardancy.

3. Anti static type: Polyurethane materials have extremely strong anti-static properties. It eliminates the problem of sparks caused by friction with steel wire ropes and is suitable for use in situations with explosives such as gas and coal dust.

At the very beginning of formulating a solution, our engineers will predict the faults that might occur during the equipment utilization relying on their rich experience, and avoid quality risks in advance.

Before getting inside the warehouse, all steel plates must be pretreated and testified to be qualified.

There is quality inspection in every process. The previous process can be allowed to enter the next one only if it is qualified. The whole process inspection records must be well preserved.

Before delivery, all the transfer carts/trolleys must undergo performance test, including load forward and backward, obstacle avoidance, omnidirectional mobile, slope climbing, lifting, wireless remote control, etc.